Forging block and subsequent machining

Features

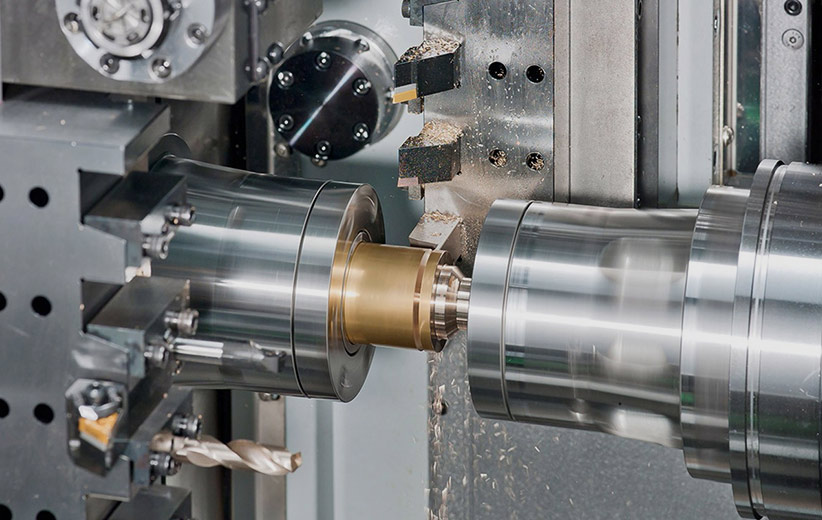

Forging block machining is an important process that helps shape and create filigree shapes. This process can be classified into two types: open-die drop forging and eccentric forging. Both involve the shaping of metal in a forging process. The former involves the placement of the block into a mold-like metal die. This is the most traditional type of forging. The open-die method entails superheating the steel and hammering it on a stationary anvil. The hot metal flows into the die and the block is then reworked.

Forging block machining involves shaping and creating parts from blank forging stocks. A die is used to shape the metal by using an impression die. The blocker impression removes details that could restrict the flow of metal. In addition, it also reduces the die wear during the finishing impression. The result is a more accurate and high-quality part. Forging block machining is an essential process for the production of forged parts.

Specification

|

item |

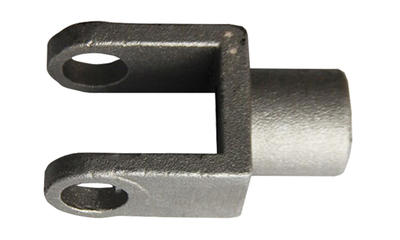

forging parts |

|

Place of Origin |

China Zhejiang |

|

Brand Name |

nbkeming |

|

Model Number |

KM-F002 |

|

Material |

Carbon steel, alloy steel, stainless steel |

|

Size |

Customized according to customer's requirements |

|

Features |

OEM processing customization |

|

Usage |

Auto parts, agricultural machinery, construction machinery, metal products, outdoor metal products, hydraulic parts |

LATEST NEWS

Our Craft

Reliable steel casting manufacturer

Specializing in the manufacturing of lost wax investment castings and finished products in carbon steel and low alloy steel, is a supplier of investment castings with water glass process in China. We are also leading OEM Forging block and subsequent machining manufacturers.

It consists of 2 major facilities, both steel casting foundry and CNC machining factory which enable us to supply both precision castings and finished products with an annual production capacity of over 10000 tons, and the products are mainly exported to Europe, America, Japan and other destinations around the world. We own Advanced foundry that custom Forging block and subsequent machining.

Our Casting Process >>

-

CASTING

-

HEAT TREATMENT

-

CNC MACHINING

-

PACKAGE

Certified

Contact Us

Related Products

-

Customized High Qualtiy Stainless Steel ...

-

Investment/Lost Wax/Precision/Metal Cast...

-

Factory Custom Brass Investment Casting ...

-

Factory High Precise Custom Cast Electr ...

-

One Stop Service Investment Casting Galv...

-

Factory Custom Machinery Metal Cast Stee...

-

Custom Lost Wax Casting Engine Flanged B...

-

Customized carbon steel casting stainles...

-

Customized precision casting company use...

-

China Factory Investment Casting Galvani...

-

EM agricultural lost wax casting agricul...

-

OEM steel precision casting parts

English

English Español

Español

Add: Xichemen Industrial Zone,Jia Village,YunlongTown, Yinzhou District,Ningbo,Zhejiang,China.

Add: Xichemen Industrial Zone,Jia Village,YunlongTown, Yinzhou District,Ningbo,Zhejiang,China.  Phone: +86-13968296962

Phone: +86-13968296962 Fax: +86-0574-88473389

Fax: +86-0574-88473389 Email:

Email: