autogrip wheel lift use in transportation equipment for agriculture and Industry

Features

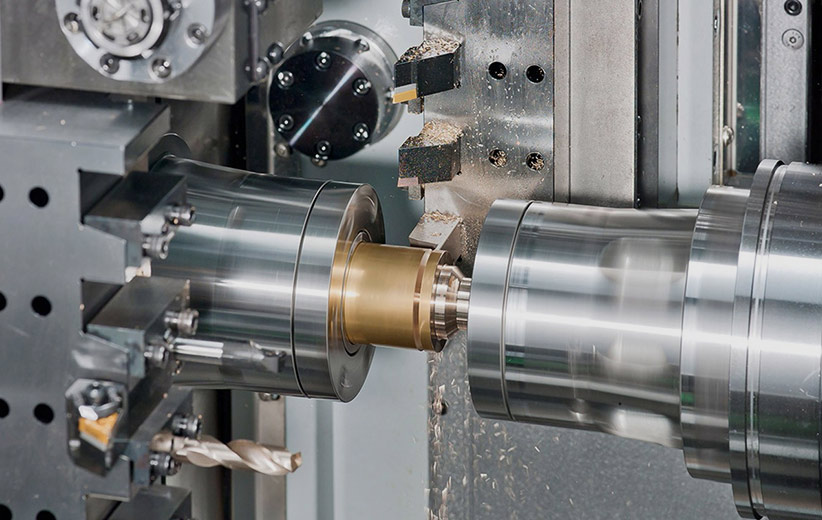

The process of molding is also highly effective, as it yields better tolerances. This method is suitable for smaller-scale production runs, because the cost of the mold and the tool are very low. It is highly cost-effective for prototypes, as it involves minimal wear and tear. But the machining process is expensive and requires high investment, especially if you need large-scale productions. For large-scale production runs, a CNC machining process is the most cost-effective option.

While casting and CNC machining have similar advantages and disadvantages, CNC machining has more precise control and is more accurate. Moreover, this method offers a better finish. During the casting process, the part is cooled to an ideal temperature and is then cast. This process is also highly efficient. It is possible to change the material after casting to make it stronger and more durable. In addition, CNC machining produces less waste, which is a great asset in many production runs.

Specification

|

item |

machining parts |

|

Place of Origin |

China Zhejiang |

|

Brand Name |

nbkeming |

|

Model Number |

KM-M012 |

|

Material |

Carbon steel, alloy steel, stainless steel |

|

Size |

Customized according to customer's requirements |

|

Features |

OEM processing customization |

|

Usage |

Auto parts, agricultural machinery, construction machinery, metal products, outdoor metal products, hydraulic parts |

LATEST NEWS

Our Craft

Reliable steel casting manufacturer

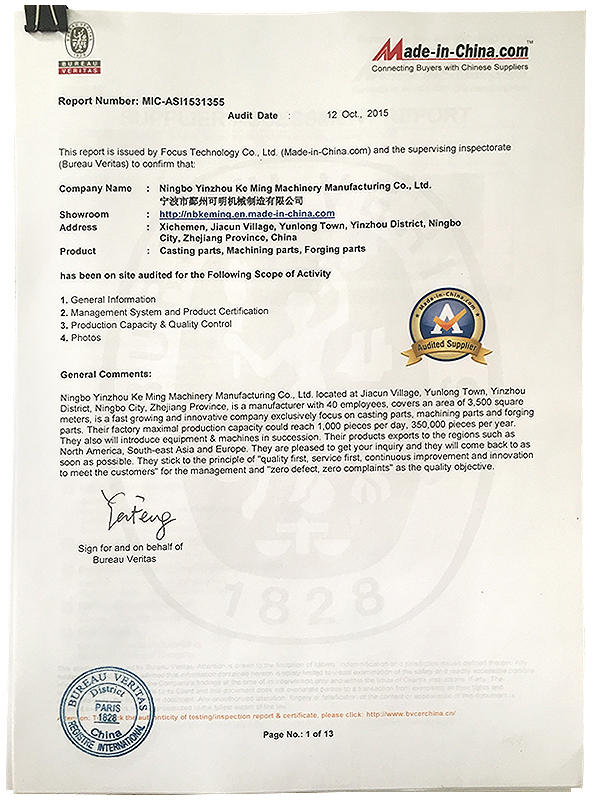

Specializing in the manufacturing of lost wax investment castings and finished products in carbon steel and low alloy steel, is a supplier of investment castings with water glass process in China. We are also leading OEM autogrip wheel lift use in transportation equipment for agriculture and Industry manufacturers.

It consists of 2 major facilities, both steel casting foundry and CNC machining factory which enable us to supply both precision castings and finished products with an annual production capacity of over 10000 tons, and the products are mainly exported to Europe, America, Japan and other destinations around the world. We own Advanced foundry that custom autogrip wheel lift use in transportation equipment for agriculture and Industry.

Our Casting Process >>

-

CASTING

-

HEAT TREATMENT

-

CNC MACHINING

-

PACKAGE

Certified

Contact Us

Related Products

-

Customized High Qualtiy Stainless Steel ...

-

Feed port mirror polishing, investment c...

-

Customized High Quality Stainless Steel ...

-

Customized High Precision Stainless Stee...

-

Customized CNC Machining Polishing Plati...

-

Forklift steering knuckle, left and righ...

-

Farm Implements Agricultural Machinery P...

-

Pump Valve Fittings Lost Wax Investment ...

-

Manufacturer Custom Made Lost Wax Cheap ...

-

Factory Custom Machinery Metal Cast Stee...

-

Factory Custom Metal Alloy Parts Cast St...

-

Customized Carbon Alloy Speciality Inves...

English

English Español

Español

Add: Xichemen Industrial Zone,Jia Village,YunlongTown, Yinzhou District,Ningbo,Zhejiang,China.

Add: Xichemen Industrial Zone,Jia Village,YunlongTown, Yinzhou District,Ningbo,Zhejiang,China.  Phone: +86-13968296962

Phone: +86-13968296962 Fax: +86-0574-88473389

Fax: +86-0574-88473389 Email:

Email: