China Factory Investment Casting Galvanized Steel Coupling

Features

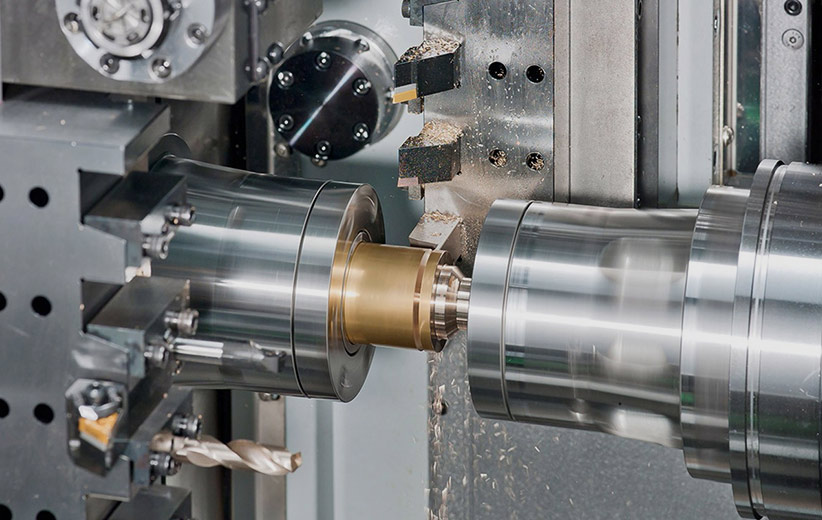

Before you can begin the process of Metal Parts Casting, you need to prepare the mold. A mold is a specially designed piece of metal used to create the final product. It is placed in a space that will flood with material. Once the mold is filled, the parts can be lifted and stacked. Once the casting process is complete, the parts are ready for use. The mold is then removed from the final product, leaving a hole in the finished product.

Computer simulation is an important tool for achieving the desired quality and cost-effectiveness of metal casting. Using the simulation tool, engineers can meet the specific requirements of a part without the need to do expensive prototypes. This method is a cost-effective way to produce parts that meet strict specifications.

There are many ways to improve the quality of metal parts. One way is to use computer simulation. This software allows you to create a two-piece, non-destructible metal mold. This mold can be used to produce identical parts for industrial applications. However, it may not be the most efficient way to manufacture metal parts. A successful application will require a good deal of planning.

Specification

|

item |

steel casting |

|

Place of Origin |

China Zhejiang |

|

Brand Name |

nbkeming |

|

Model Number |

KM-SC034 |

|

Material |

Carbon steel, alloy steel, stainless steel |

|

Size |

Customized according to customer's requirements |

|

Features |

OEM processing customization |

|

Usage |

Auto parts, agricultural machinery, construction machinery, metal products, outdoor metal products, hydraulic parts |

LATEST NEWS

Our Craft

Reliable steel casting manufacturer

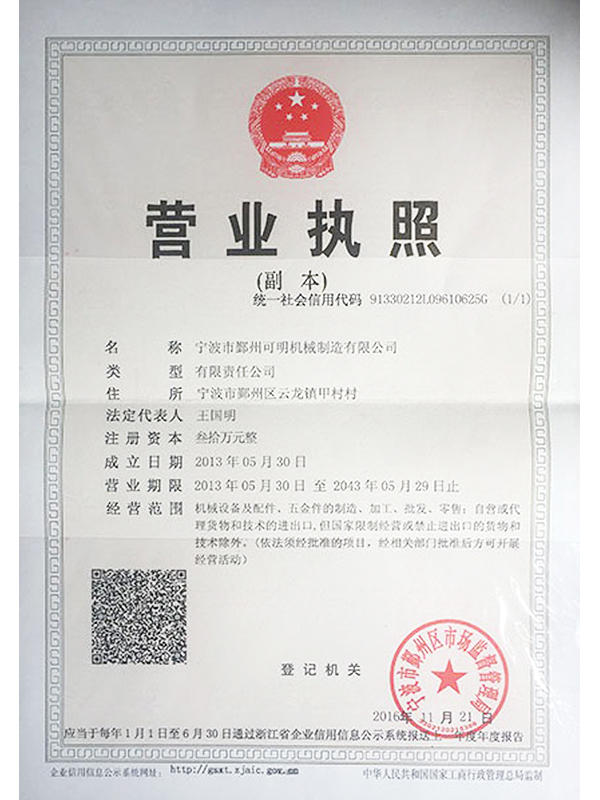

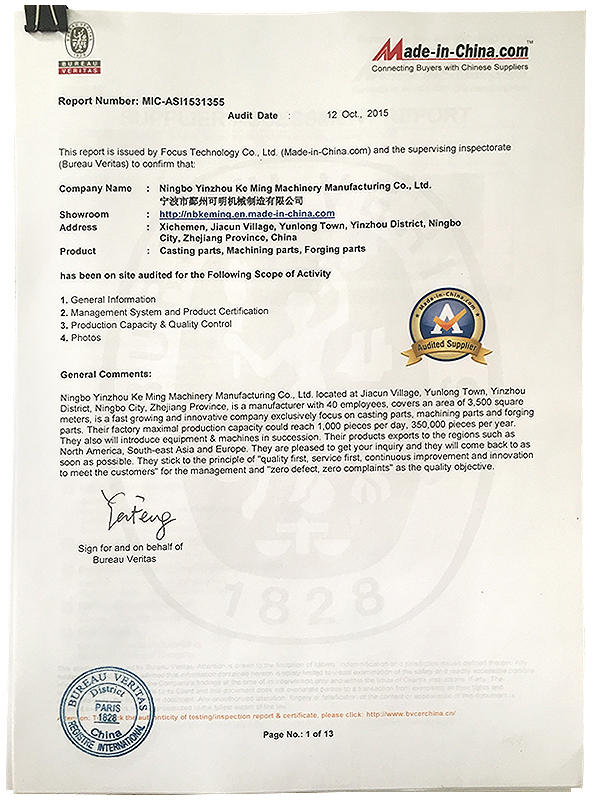

Specializing in the manufacturing of lost wax investment castings and finished products in carbon steel and low alloy steel, is a supplier of investment castings with water glass process in China. We are also leading OEM China Factory Investment Casting Galvanized Steel Coupling manufacturers.

It consists of 2 major facilities, both steel casting foundry and CNC machining factory which enable us to supply both precision castings and finished products with an annual production capacity of over 10000 tons, and the products are mainly exported to Europe, America, Japan and other destinations around the world. We own Advanced foundry that custom China Factory Investment Casting Galvanized Steel Coupling.

Our Casting Process >>

-

CASTING

-

HEAT TREATMENT

-

CNC MACHINING

-

PACKAGE

Certified

Contact Us

Related Products

-

The steering wheel spokes are mirror pol...

-

Customized High Quality Stainless Steel ...

-

Investment/Lost Wax/Precision/Metal Cast...

-

Customized High Quality Stainless Steel ...

-

Mining machinery hooks castings, high te...

-

OEM Customized Service Carbon Steel Cast...

-

Farm Implements Agricultural Machinery P...

-

Precisely Fabrication Custom Alloy Steel...

-

One Stop Service Investment Casting Galv...

-

Customized carbon steel casting stainles...

-

Customized lost wax casting steel precis...

-

Custom Metal Foundry Precision Stainless...

English

English Español

Español

Add: Xichemen Industrial Zone,Jia Village,YunlongTown, Yinzhou District,Ningbo,Zhejiang,China.

Add: Xichemen Industrial Zone,Jia Village,YunlongTown, Yinzhou District,Ningbo,Zhejiang,China.  Phone: +86-13968296962

Phone: +86-13968296962 Fax: +86-0574-88473389

Fax: +86-0574-88473389 Email:

Email: