Customized lost wax casting steel precision investment casting process

Features

When choosing excavator bucket teeth, the correct selection of the material for the bucket teeth is very important. The teeth should be made of hard steel with long grain steel so that they can be durable and high-performance. If the toothed sleeve is not hard enough, it will break easily upon impact. If the bucket teeth are not hard enough, the impact forces can weaken the material's impact toughness, resulting in premature wear and failure.

In addition to the bucket's shape, the teeth are important for the efficiency of the excavator. Its size determines the force of the machine. The wide teeth should be wider than the narrow ones. The narrower buckets should be used in situations where the bucket can't move too far. Those with sharp teeth should be removed immediately. The gap between the bucket teeth is a sign that the teeth need to be repaired.

In addition to the size and shape of the teeth, they should also be of the proper design to fit the bucket. Ideally, they should be sharp and not curved at an angle. This way, they'll reduce the amount of pressure applied to the bucket.

Specification

|

item |

steel casting |

|

Place of Origin |

China Zhejiang |

|

Brand Name |

nbkeming |

|

Model Number |

KM-SC028 |

|

Material |

Carbon steel, alloy steel, stainless steel |

|

Size |

Customized according to customer's requirements |

|

Features |

OEM processing customization |

|

Usage |

Auto parts, agricultural machinery, construction machinery, metal products, outdoor metal products, hydraulic parts |

LATEST NEWS

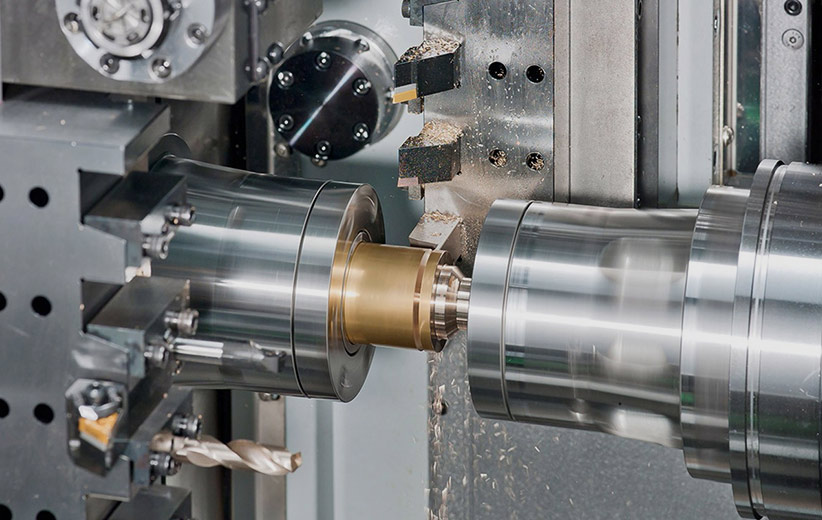

Our Craft

Reliable steel casting manufacturer

Specializing in the manufacturing of lost wax investment castings and finished products in carbon steel and low alloy steel, is a supplier of investment castings with water glass process in China. We are also leading OEM Customized lost wax casting steel precision investment casting process manufacturers.

It consists of 2 major facilities, both steel casting foundry and CNC machining factory which enable us to supply both precision castings and finished products with an annual production capacity of over 10000 tons, and the products are mainly exported to Europe, America, Japan and other destinations around the world. We own Advanced foundry that custom Customized lost wax casting steel precision investment casting process.

Our Casting Process >>

-

CASTING

-

HEAT TREATMENT

-

CNC MACHINING

-

PACKAGE

Certified

Contact Us

Related Products

-

Investment/Lost Wax/Precision/Metal Cast...

-

Customized High Quality Stainless Steel ...

-

Customized High Precision Stainless Stee...

-

The Most Professional Casting Factory Pi...

-

Customized CNC Machining Polishing Plati...

-

Customized CNC Machining Polishing Plati...

-

Custom Made Lost Wax Casting Carbon Stee...

-

Manufacturer Custom Made Lost Wax Cheap ...

-

Factory Custom Metal Alloy Parts Cast St...

-

Customized lost wax casting steel precis...

-

Mechanical Processing Lost Wax Valve Par...

-

OEM Investment Precision Casting Parts f...

English

English Español

Español

Add: Xichemen Industrial Zone,Jia Village,YunlongTown, Yinzhou District,Ningbo,Zhejiang,China.

Add: Xichemen Industrial Zone,Jia Village,YunlongTown, Yinzhou District,Ningbo,Zhejiang,China.  Phone: +86-13968296962

Phone: +86-13968296962 Fax: +86-0574-88473389

Fax: +86-0574-88473389 Email:

Email: