Pump Valve Fittings Lost Wax Investment Casting

Features

Investment Casting is a pouring process for producing complex components. This method is far superior to forging because it allows for much more precise, complex shapes and is less costly. Moreover, it produces parts in a shorter amount of time compared to other methods.

The process of investment casting relies on a ceramic mold. This mold is turned upside down and heated to 200-375 degrees Fahrenheit. This causes the wax to flow out of the mold, leaving a cavity for the metal to be cast. Once the wax dries, the mold is destroyed, leaving a part that is perfectly fit. Unlike the process of casting in clay, investment casting does not require machining, thereby improving the product quality.

Compared to traditional casting methods, investment casting reduces waste, improves product quality, reduces return rates, and increases the predictability of the supply chain. A major benefit of investment casting is that it is highly customizable. It is a great choice for small-scale manufacturing. The process of investment casting has become an important part of almost all industries, including automobile, aerospace, and automotive industries.

Specification

|

item |

steel casting |

|

Place of Origin |

China Zhejiang |

|

Brand Name |

nbkeming |

|

Model Number |

KM-SC015 |

|

Material |

Carbon steel, alloy steel, stainless steel |

|

Size |

Customized according to customer's requirements |

|

Features |

OEM processing customization |

|

Usage |

Auto parts, agricultural machinery, construction machinery, metal products, outdoor metal products, hydraulic parts |

LATEST NEWS

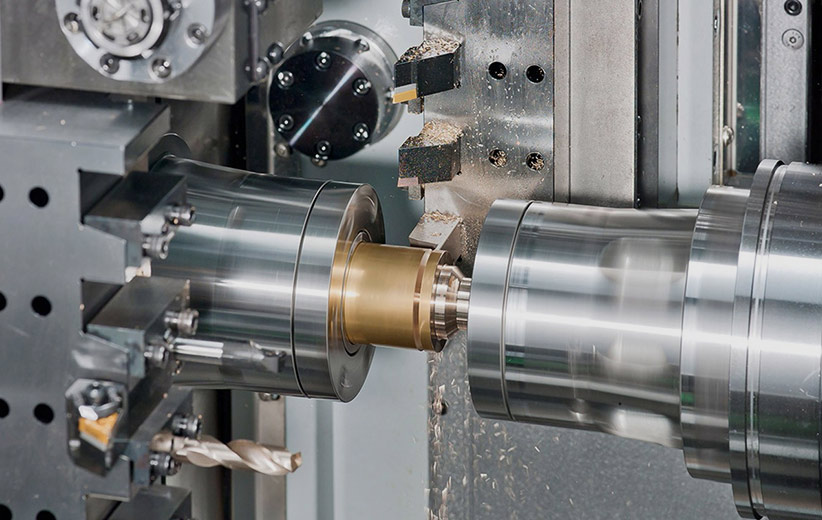

Our Craft

Reliable steel casting manufacturer

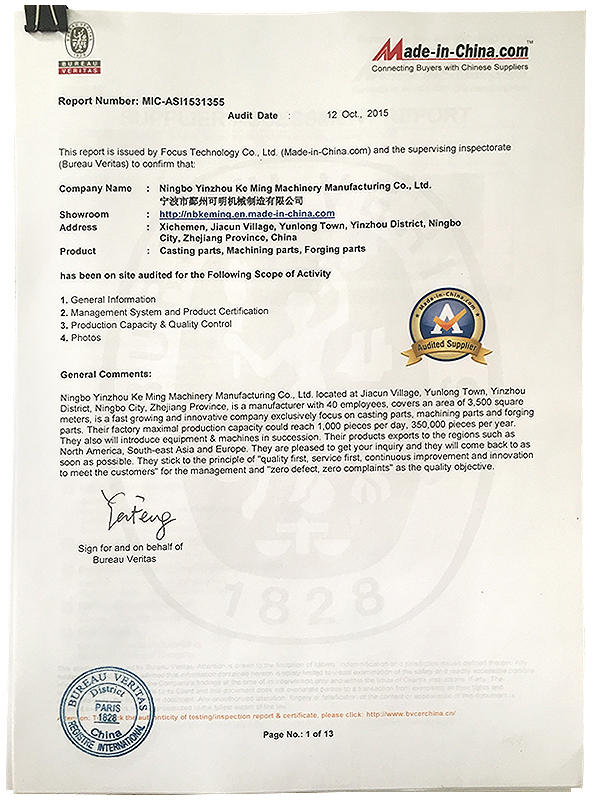

Specializing in the manufacturing of lost wax investment castings and finished products in carbon steel and low alloy steel, is a supplier of investment castings with water glass process in China. We are also leading OEM Pump Valve Fittings Lost Wax Investment Casting manufacturers.

It consists of 2 major facilities, both steel casting foundry and CNC machining factory which enable us to supply both precision castings and finished products with an annual production capacity of over 10000 tons, and the products are mainly exported to Europe, America, Japan and other destinations around the world. We own Advanced foundry that custom Pump Valve Fittings Lost Wax Investment Casting.

Our Casting Process >>

-

CASTING

-

HEAT TREATMENT

-

CNC MACHINING

-

PACKAGE

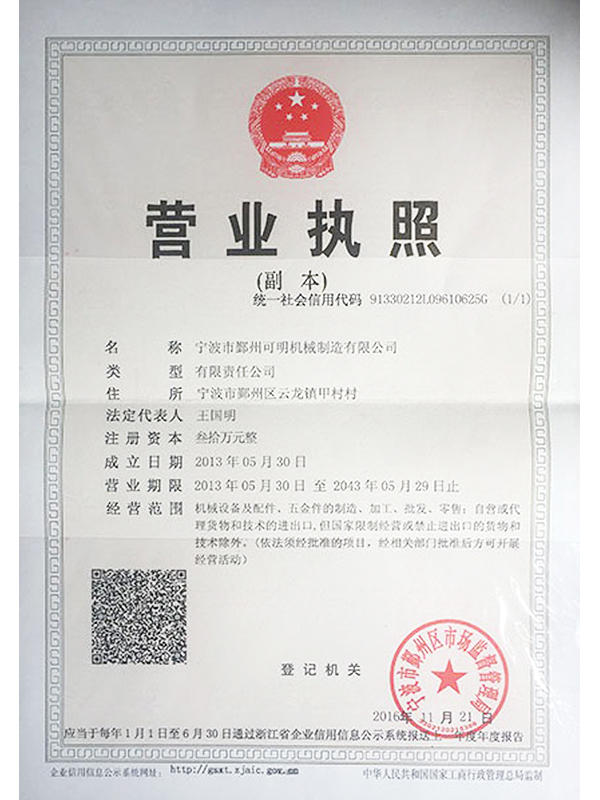

Certified

Contact Us

Related Products

-

Customized High Quality Stainless Steel ...

-

Valve Body lost wax stainless steel cast...

-

Factory Foundry Metal Silica Sol/Lost W...

-

The Most Professional Casting Factory Pi...

-

Forklift steering knuckle, left and righ...

-

Factory Custom Brass Investment Casting ...

-

Pump Valve Fittings Lost Wax Investment ...

-

Factory Custom Metal Alloy Parts Cast St...

-

Customized carbon steel casting stainles...

-

Customized carbon steel precision castin...

-

Mechanical Processing Lost Wax Valve Par...

-

Customized Lost Wax Machinery Parts Stee...

English

English Español

Español

Add: Xichemen Industrial Zone,Jia Village,YunlongTown, Yinzhou District,Ningbo,Zhejiang,China.

Add: Xichemen Industrial Zone,Jia Village,YunlongTown, Yinzhou District,Ningbo,Zhejiang,China.  Phone: +86-13968296962

Phone: +86-13968296962 Fax: +86-0574-88473389

Fax: +86-0574-88473389 Email:

Email: