Steel Forging Parts, Open Die Forging, Hot Forging Parts, Drop Forging for Gear, Shaft, Tube, Ring

Features

The primary advantage of forging is that the metal retains its grain structure and alignment. In addition, preprocessing and preworking remove contaminants, which are typically found in other forms of metalworking. This ensures that metals solidify flawlessly. The process also helps in improving the strength and durability of the forged products. Ultimately, steel forging parts are the most cost-effective form of metalworking.

The main advantage of steel forging is that it is more durable. It can withstand higher temperatures and greater loads than any other type of metal. Since it is a more precise process, it improves overall efficiency. Moreover, it is more efficient than other methods in terms of scrap. Unlike casting steel, forgings don't require additional secondary operations after they have been forged. Generally, steel bars and plates require additional operations to remove surface irregularities.

The biggest advantage of steel forgings is their strength. Forging is a tougher metal than other steel processes. It can be used in swords, and its strength is not affected by water. Its improved strength makes it ideal for weapons. They are also suitable for cutting. It is a process of hammering and cooling that makes forged parts stronger and tougher. The forging process is a complex one. The forging of a metal part requires precision and skill.

Specification

|

item |

forging parts |

|

Place of Origin |

China Zhejiang |

|

Brand Name |

nbkeming |

|

Model Number |

KM-F007 |

|

Material |

Carbon steel, alloy steel, stainless steel |

|

Size |

Customized according to customer's requirements |

|

Features |

OEM processing customization |

|

Usage |

Auto parts, agricultural machinery, construction machinery, metal products, outdoor metal products, hydraulic parts |

LATEST NEWS

Our Craft

Reliable steel casting manufacturer

Specializing in the manufacturing of lost wax investment castings and finished products in carbon steel and low alloy steel, is a supplier of investment castings with water glass process in China. We are also leading OEM Steel Forging Parts, Open Die Forging, Hot Forging Parts, Drop Forging for Gear, Shaft, Tube, Ring manufacturers.

It consists of 2 major facilities, both steel casting foundry and CNC machining factory which enable us to supply both precision castings and finished products with an annual production capacity of over 10000 tons, and the products are mainly exported to Europe, America, Japan and other destinations around the world. We own Advanced foundry that custom Steel Forging Parts, Open Die Forging, Hot Forging Parts, Drop Forging for Gear, Shaft, Tube, Ring.

Our Casting Process >>

-

CASTING

-

HEAT TREATMENT

-

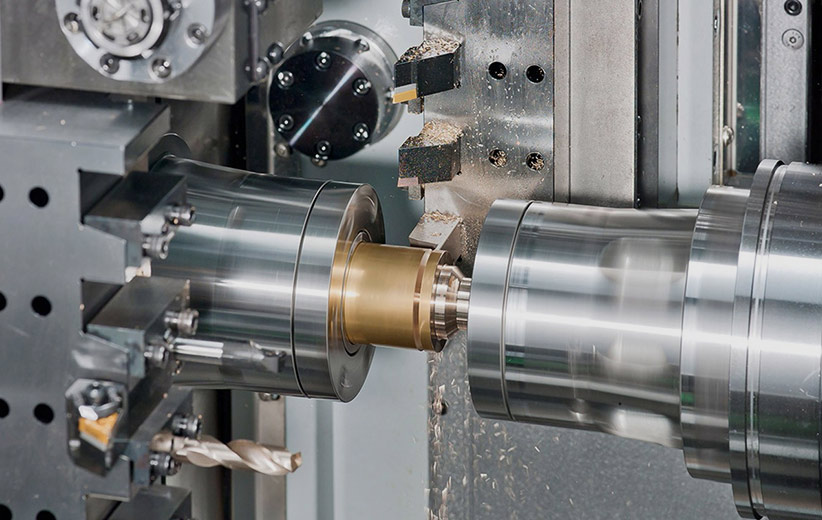

CNC MACHINING

-

PACKAGE

Certified

Contact Us

Related Products

-

The steering wheel spokes are mirror pol...

-

Customized High Qualtiy Stainless Steel ...

-

Feed port mirror polishing, investment c...

-

Customized High Quality Stainless Steel ...

-

Customized CNC Machining Polishing Plati...

-

Fabricated Custom Made Alloy Steel Casti...

-

Cast counterweight model from China

-

Precisely Fabrication Custom Alloy Steel...

-

China Factory Oem Custom Service Parts S...

-

Steel Lost Wax Casting Motorcycle Parts ...

-

Customized precision casting company use...

-

Customized Lost Wax Machinery Parts Stee...

English

English Español

Español

Add: Xichemen Industrial Zone,Jia Village,YunlongTown, Yinzhou District,Ningbo,Zhejiang,China.

Add: Xichemen Industrial Zone,Jia Village,YunlongTown, Yinzhou District,Ningbo,Zhejiang,China.  Phone: +86-13968296962

Phone: +86-13968296962 Fax: +86-0574-88473389

Fax: +86-0574-88473389 Email:

Email: