Aluminum heat dissipation pulley is precision machined and the surface is anodized

Features

The process is most suitable for low-volume production and smaller parts. However, it requires a large amount of inert material for the mold and can produce large pieces up to twenty kilograms. Depending on the material, the heat dissipation pulley casting can produce complex forms with few blowholes or pockets. Another advantage of this process is the high level of accuracy. You can expect the cast to be accurate within a few millimeters and a few millimetres.

When it comes to casting parts for heat dissipation, the process is an efficient and effective solution. It allows manufacturers to create intricate parts up to 20kg and maintain dimensional accuracy. It also allows them to produce small parts up to 200kg/h. With the right design, this process can produce high-volume components with little or no effort. It is ideal for low-volume production. But, in some cases, the part size is too large.

Specification

|

item |

machining parts |

|

Place of Origin |

China Zhejiang |

|

Brand Name |

nbkeming |

|

Model Number |

KM-M029 |

|

Material |

Carbon steel, alloy steel, stainless steel |

|

Size |

Customized according to customer's requirements |

|

Features |

OEM processing customization |

|

Usage |

Auto parts, agricultural machinery, construction machinery, metal products, outdoor metal products, hydraulic parts |

LATEST NEWS

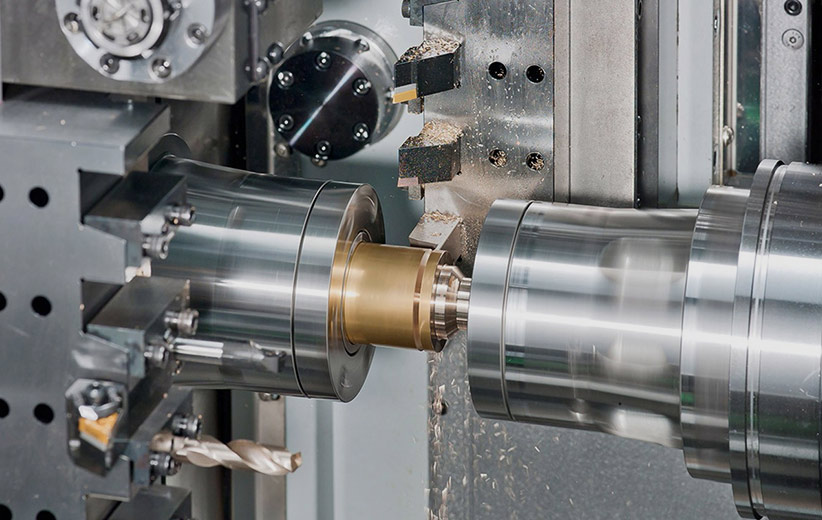

Our Craft

Reliable steel casting manufacturer

Specializing in the manufacturing of lost wax investment castings and finished products in carbon steel and low alloy steel, is a supplier of investment castings with water glass process in China. We are also leading OEM Aluminum heat dissipation pulley is precision machined and the surface is anodized manufacturers.

It consists of 2 major facilities, both steel casting foundry and CNC machining factory which enable us to supply both precision castings and finished products with an annual production capacity of over 10000 tons, and the products are mainly exported to Europe, America, Japan and other destinations around the world. We own Advanced foundry that custom Aluminum heat dissipation pulley is precision machined and the surface is anodized.

Our Casting Process >>

-

CASTING

-

HEAT TREATMENT

-

CNC MACHINING

-

PACKAGE

Certified

Contact Us

Related Products

-

Feed port mirror polishing, investment c...

-

Investment/Lost Wax/Precision/Metal Cast...

-

Customized High Quality Stainless Steel ...

-

OEM Customized Service Carbon Steel Cast...

-

Manufacturer Custom Made Lost Wax Cheap ...

-

Factory High Precise Custom Cast Electr ...

-

Custom Cast Steel Lost Wax Casting Strok...

-

Custom Lost Wax Casting Engine Flanged B...

-

Customized carbon steel precision castin...

-

CNC lathes investment castings foundry O...

-

OEM steel lost wax investment cast auto ...

-

Customized Lost Wax Machinery Parts Stee...

English

English Español

Español

Add: Xichemen Industrial Zone,Jia Village,YunlongTown, Yinzhou District,Ningbo,Zhejiang,China.

Add: Xichemen Industrial Zone,Jia Village,YunlongTown, Yinzhou District,Ningbo,Zhejiang,China.  Phone: +86-13968296962

Phone: +86-13968296962 Fax: +86-0574-88473389

Fax: +86-0574-88473389 Email:

Email: