Cast steel Electrode For Furnace Parts and Boiler Accessories Castings

Features

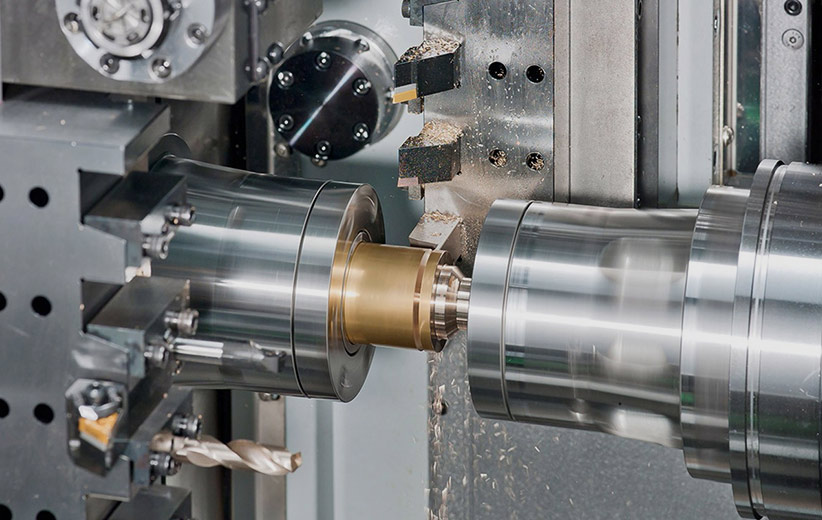

The main process for casting automobile parts involves pouring liquid metal into a mold to produce components with the necessary dimensional accuracy. Any metal can be cast, though iron, aluminum, and steel are the most popular materials for this process.

While you might be wondering how the process works, you can find out more about the various types of castings. There are centrifugal and green sand casting. These are all types of automotive parts, and the different processes can vary greatly depending on the material used. However, green sand and lost-foam casting are the most popular. Moreover, both methods are highly durable and can withstand extreme temperatures.

The process of casting is a process of pouring liquid metal into a mold to produce dimensionally accurate components. It can be used to create a variety of automotive parts, including brake rotors, wheel hubs, and engine components. Besides being a great way to reduce the overall weight of a car, it also reduces fuel consumption. It also helps in reducing the weight of the car, which is very important for the environment.

Specification

|

item |

steel casting |

|

Place of Origin |

China Zhejiang |

|

Brand Name |

nbkeming |

|

Model Number |

KM-SC071 |

|

Material |

Carbon steel, alloy steel, stainless steel |

|

Size |

Customized according to customer's requirements |

|

Features |

OEM processing customization |

|

Usage |

Auto parts, agricultural machinery, construction machinery, metal products, outdoor metal products, hydraulic parts |

LATEST NEWS

Our Craft

Reliable steel casting manufacturer

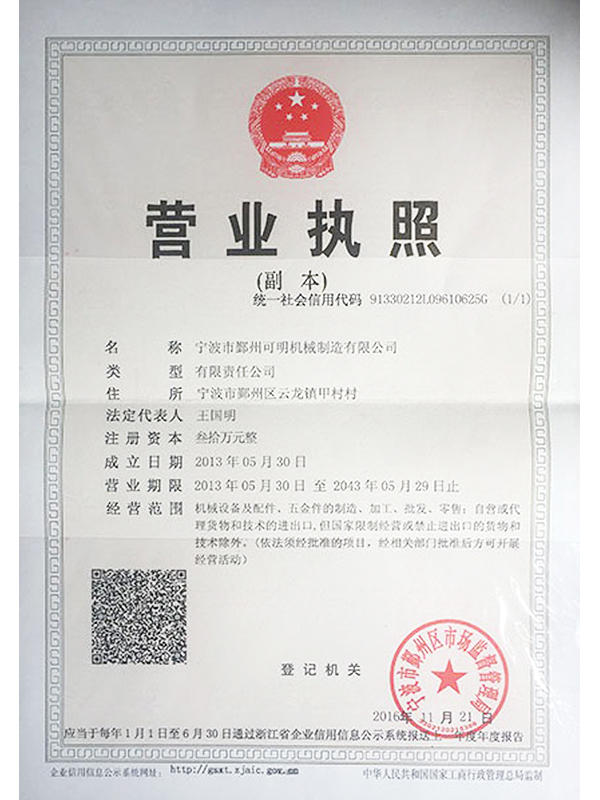

Specializing in the manufacturing of lost wax investment castings and finished products in carbon steel and low alloy steel, is a supplier of investment castings with water glass process in China. We are also leading OEM Cast steel Electrode For Furnace Parts and Boiler Accessories Castings manufacturers.

It consists of 2 major facilities, both steel casting foundry and CNC machining factory which enable us to supply both precision castings and finished products with an annual production capacity of over 10000 tons, and the products are mainly exported to Europe, America, Japan and other destinations around the world. We own Advanced foundry that custom Cast steel Electrode For Furnace Parts and Boiler Accessories Castings.

Our Casting Process >>

-

CASTING

-

HEAT TREATMENT

-

CNC MACHINING

-

PACKAGE

Certified

Contact Us

Related Products

-

Feed port mirror polishing, investment c...

-

Valve Body lost wax stainless steel cast...

-

Fabricated Custom Made Alloy Steel Casti...

-

Forklift steering knuckle, left and righ...

-

Custom Made Lost Wax Casting Carbon Stee...

-

Manufacturer Custom Made Lost Wax Cheap ...

-

Factory High Precise Custom Cast Electr ...

-

Steel Lost Wax Casting Motorcycle Parts ...

-

Manufacture Custom Made Lost Wax Casting...

-

Factory Custom Metal Alloy Parts Cast St...

-

Customized carbon steel casting stainles...

-

OEM Investment Precision Casting Parts f...

English

English Español

Español

Add: Xichemen Industrial Zone,Jia Village,YunlongTown, Yinzhou District,Ningbo,Zhejiang,China.

Add: Xichemen Industrial Zone,Jia Village,YunlongTown, Yinzhou District,Ningbo,Zhejiang,China.  Phone: +86-13968296962

Phone: +86-13968296962 Fax: +86-0574-88473389

Fax: +86-0574-88473389 Email:

Email: