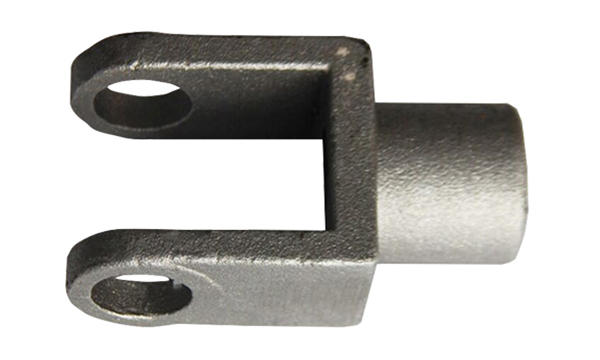

EM agricultural lost wax casting agricultural machinery casting parts

Features

There are many benefits of using a design for manufacturing process when casting parts. During the production process, specific guidelines are used to create a part that will be as precise as possible. This method also helps to cut costs and simplify the production process.

Raised and embedded letters: Rounded ribs are ideal for reducing rapid changes in the flow of molten metal. They also help reduce quick changes in cross-sections and corners, which will increase the efficiency of casting processes. A ribged part has an odd number of ribs, which eliminates stress build-up between adjacent ridges. This helps reduce the risk of thick intersections and ensures better ejection of the casting.

Design Casting: When designing for design casting, designers can create intricate parts with fine details. When designing for design casting, designers should avoid interior undercuts that may interfere with moving core mechanics. The extra cost of tools will be offset by lower part cost.

Specification

|

item |

steel casting |

|

Place of Origin |

China Zhejiang |

|

Brand Name |

nbkeming |

|

Model Number |

KM-SC035 |

|

Material |

Carbon steel, alloy steel, stainless steel |

|

Size |

Customized according to customer's requirements |

|

Features |

OEM processing customization |

|

Usage |

Auto parts, agricultural machinery, construction machinery, metal products, outdoor metal products, hydraulic parts |

LATEST NEWS

Our Craft

Reliable steel casting manufacturer

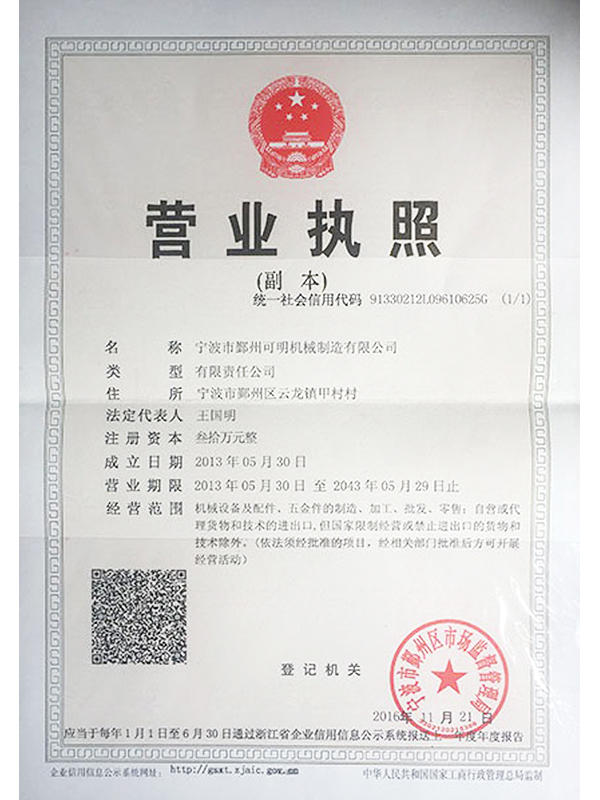

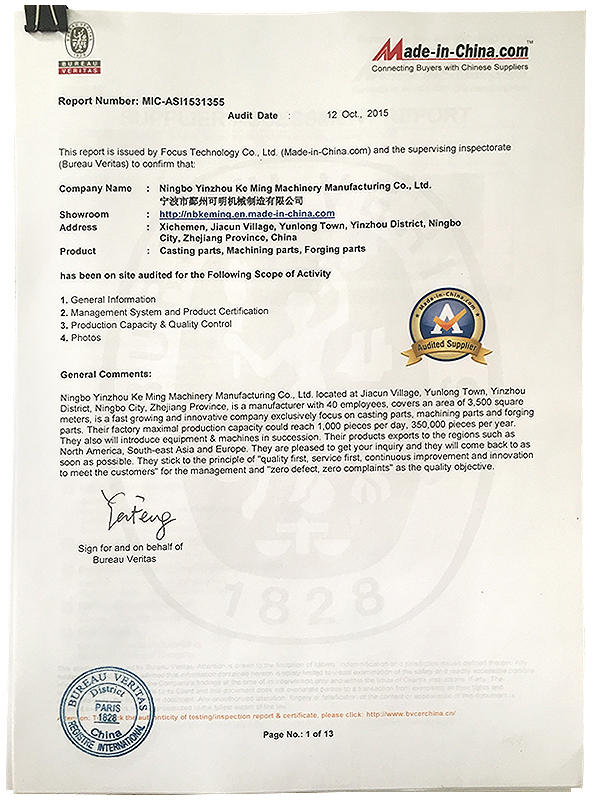

Specializing in the manufacturing of lost wax investment castings and finished products in carbon steel and low alloy steel, is a supplier of investment castings with water glass process in China. We are also leading OEM EM agricultural lost wax casting agricultural machinery casting parts manufacturers.

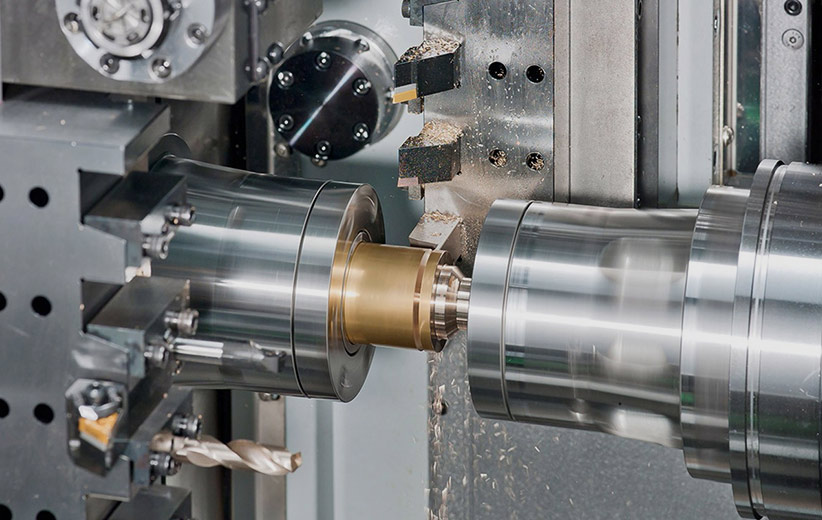

It consists of 2 major facilities, both steel casting foundry and CNC machining factory which enable us to supply both precision castings and finished products with an annual production capacity of over 10000 tons, and the products are mainly exported to Europe, America, Japan and other destinations around the world. We own Advanced foundry that custom EM agricultural lost wax casting agricultural machinery casting parts.

Our Casting Process >>

-

CASTING

-

HEAT TREATMENT

-

CNC MACHINING

-

PACKAGE

Certified

Contact Us

Related Products

-

Customized CNC Machining Polishing Plati...

-

Fabricated Custom Made Alloy Steel Casti...

-

Fabricated Custom Made Alloy Steel Casti...

-

Manufacturer Custom Made Lost Wax Cheap ...

-

Factory High Precise Custom Cast Electr ...

-

Manufacture Custom Made Lost Wax Casting...

-

Factory Custom Metal Alloy Parts Cast St...

-

Customized carbon steel casting stainles...

-

CNC lathes investment castings foundry O...

-

Custom Metal Foundry Precision Stainless...

-

China Factory Investment Casting Galvani...

-

OEM Investment Precision Casting Parts f...

English

English Español

Español

Add: Xichemen Industrial Zone,Jia Village,YunlongTown, Yinzhou District,Ningbo,Zhejiang,China.

Add: Xichemen Industrial Zone,Jia Village,YunlongTown, Yinzhou District,Ningbo,Zhejiang,China.  Phone: +86-13968296962

Phone: +86-13968296962 Fax: +86-0574-88473389

Fax: +86-0574-88473389 Email:

Email: