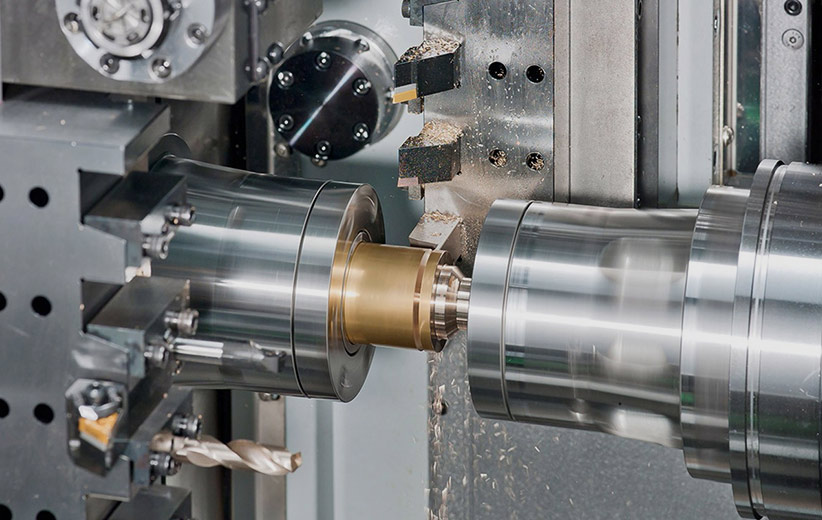

High precision spiral oil groove machining, CNC turning and milling

Features

Spiral oil groove machining is a process in which the groove is cut in a single piece. It is also called as "spiral-cross" or "cross-spiral grooving". However, the spiral-cross pattern is more common. Besides, these patterns can be used in both wet and dry applications. Spiral oil groove machining is one of the most popular processes for spherical-spiral applications. The spiral-shaped design enables the flow of oil to be controlled without a lot of friction. Spiral-spiral grooving patterns are primarily used in sump-type applications where there is limited amount of oil.

The spiral oil groove is used for wet applications where the oil flow is required to be controlled and predictable. The sunburst oil groove is suited for applications with sufficient amounts of liquid. It facilitates high-flow of oils and minimizes drag. This pattern is best for sump-type applications with limited amount of water. A slant-type oil groove gives a controlled flow of the oil but it will have high viscosity.

Specification

|

item |

machining parts |

|

Place of Origin |

China Zhejiang |

|

Brand Name |

nbkeming |

|

Model Number |

KM-M032 |

|

Material |

Carbon steel, alloy steel, stainless steel |

|

Size |

Customized according to customer's requirements |

|

Features |

OEM processing customization |

|

Usage |

Auto parts, agricultural machinery, construction machinery, metal products, outdoor metal products, hydraulic parts |

LATEST NEWS

Our Craft

Reliable steel casting manufacturer

Specializing in the manufacturing of lost wax investment castings and finished products in carbon steel and low alloy steel, is a supplier of investment castings with water glass process in China. We are also leading OEM High precision spiral oil groove machining, CNC turning and milling manufacturers.

It consists of 2 major facilities, both steel casting foundry and CNC machining factory which enable us to supply both precision castings and finished products with an annual production capacity of over 10000 tons, and the products are mainly exported to Europe, America, Japan and other destinations around the world. We own Advanced foundry that custom High precision spiral oil groove machining, CNC turning and milling.

Our Casting Process >>

-

CASTING

-

HEAT TREATMENT

-

CNC MACHINING

-

PACKAGE

Certified

Contact Us

Related Products

-

The Most Professional Casting Factory Pi...

-

Customized CNC Machining Polishing Plati...

-

Customized CNC Machining Polishing Plati...

-

Farm Implements Agricultural Machinery P...

-

Cast counterweight model from China

-

Custom Made Lost Wax Casting Carbon Stee...

-

Pump Valve Fittings Lost Wax Investment ...

-

Precisely Fabrication Custom Alloy Steel...

-

Factory Custom Metal Alloy Parts Cast St...

-

CNC lathes investment castings foundry O...

-

China Factory Investment Casting Galvani...

-

Customized Carbon Alloy Speciality Inves...

English

English Español

Español

Add: Xichemen Industrial Zone,Jia Village,YunlongTown, Yinzhou District,Ningbo,Zhejiang,China.

Add: Xichemen Industrial Zone,Jia Village,YunlongTown, Yinzhou District,Ningbo,Zhejiang,China.  Phone: +86-13968296962

Phone: +86-13968296962 Fax: +86-0574-88473389

Fax: +86-0574-88473389 Email:

Email: