Alloy Steel Investment Casting with Machined

Features

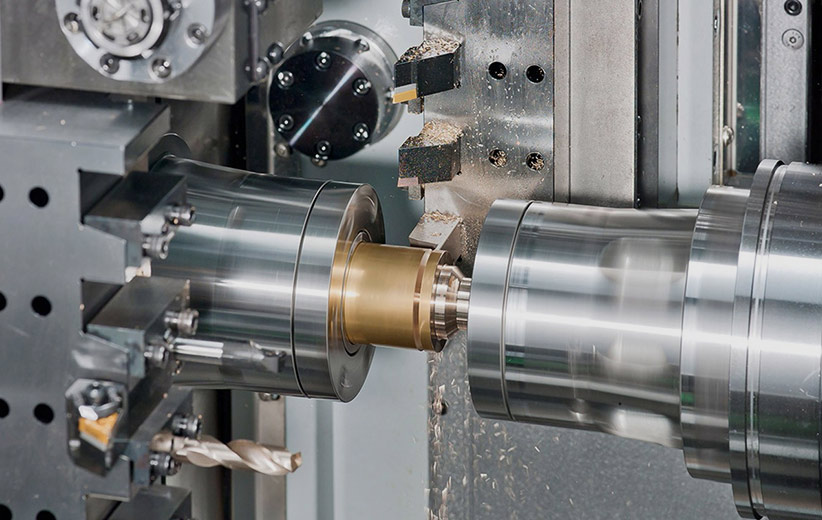

The manufacturing process of steel casting includes three steps: creating a pattern, pouring metal into a mold cavity, and cooling. During the cooling process, excess material (sprue) is removed. Once cooled, the casting is reheated to restore the material's softness and improve impact strength. The quality of the pattern used in the steel casting process is crucial to the dimensional accuracy of the final product.

The production of steel castings is mainly focused on valves and fittings. These parts are used in drilling, transportation, and refining. The weight of these components can vary from a few pounds to several tons. The pressures applied to these castings can reach thousands of p.s.i. and thousands of kPa in valves. A substantial portion of the steel casting industry is used in the construction of heavy trucks. Its range of applications includes axle housings, wheels, differential housings, and fifth wheels.

Specification

|

item |

steel casting |

|

Place of Origin |

China Zhejiang |

|

Brand Name |

nbkeming |

|

Model Number |

KM-SC058 |

|

Material |

Carbon steel, alloy steel, stainless steel |

|

Size |

Customized according to customer's requirements |

|

Features |

OEM processing customization |

|

Usage |

Auto parts, agricultural machinery, construction machinery, metal products, outdoor metal products, hydraulic parts |

LATEST NEWS

Our Craft

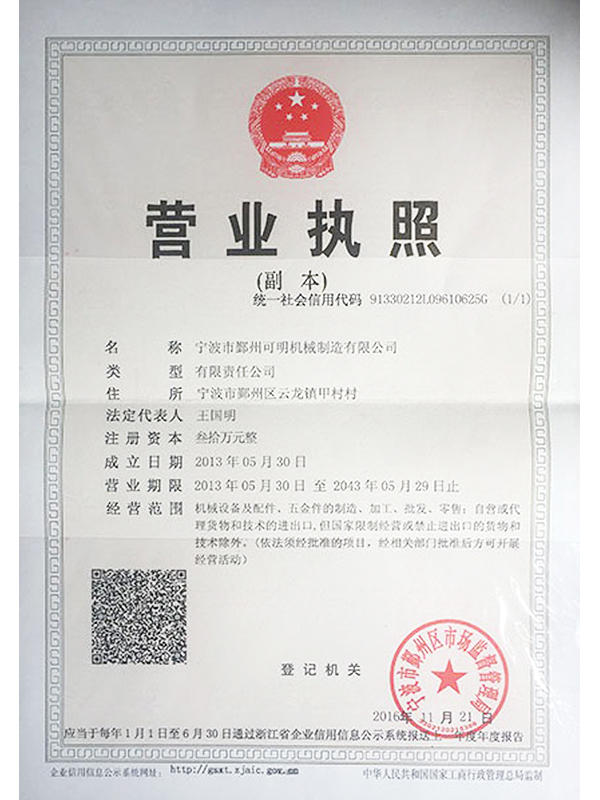

Reliable steel casting manufacturer

Specializing in the manufacturing of lost wax investment castings and finished products in carbon steel and low alloy steel, is a supplier of investment castings with water glass process in China. We are also leading OEM Alloy Steel Investment Casting with Machined manufacturers.

It consists of 2 major facilities, both steel casting foundry and CNC machining factory which enable us to supply both precision castings and finished products with an annual production capacity of over 10000 tons, and the products are mainly exported to Europe, America, Japan and other destinations around the world. We own Advanced foundry that custom Alloy Steel Investment Casting with Machined.

Our Casting Process >>

-

CASTING

-

HEAT TREATMENT

-

CNC MACHINING

-

PACKAGE

Certified

Contact Us

Related Products

-

The Most Professional Casting Factory Pi...

-

The Most Professional Casting Factory Pi...

-

Forklift steering knuckle, left and righ...

-

Cast counterweight model from China

-

Custom Made Lost Wax Casting Carbon Stee...

-

Pump Valve Fittings Lost Wax Investment ...

-

Manufacturer Custom Made Lost Wax Cheap ...

-

China Factory Oem Custom Service Parts S...

-

Steel Lost Wax Casting Motorcycle Parts ...

-

Factory Custom Metal Alloy Parts Cast St...

-

Custom Lost Wax Casting Engine Flanged B...

-

Customized lost wax casting steel precis...

English

English Español

Español

Add: Xichemen Industrial Zone,Jia Village,YunlongTown, Yinzhou District,Ningbo,Zhejiang,China.

Add: Xichemen Industrial Zone,Jia Village,YunlongTown, Yinzhou District,Ningbo,Zhejiang,China.  Phone: +86-13968296962

Phone: +86-13968296962 Fax: +86-0574-88473389

Fax: +86-0574-88473389 Email:

Email: